What is a thermal shock chamber?

RIUKAI’s Thermal Shock Chambers can be used to test the ability of most products to withstand drastic temperature changes. Simply put, a thermal shock tester can instantly subject a product to the most extreme temperature conditions. The purpose of using RIUKAI’s Thermal Shock Chamber for testing products under such conditions is to observe the change in product characteristics. To check whether different materials and coefficients of thermal expansion can lead to failure.

What is a thermal shock chamber used for?

Thermal Shock Testing – Temperature Cycling

Deciphering Thermal Shock Chamber:

In the complex landscape of industrial processes, Thermal Shock Chamber, also known as temperature test chambers, stand as essential tools serving a variety of functions. Their usage spans multiple industries and applications, showcasing versatility beyond conventional testing norms.

Demonstrating their capabilities in steady-state or stability testing, these chambers create an environment of equilibrium for products to undergo thorough scrutiny, ensuring they endure consistent conditions.

Thermal Cycling Exploration:

Engaging in thermal cycling or thermal shock processes, these chambers subject specimens to fluctuating temperatures, simulating real-world scenarios where products must withstand unpredictable thermal variations.

Adapting to Changing Needs:

In the ever-changing landscape of testing requirements, these chambers prove to be adaptable allies. Industry demands dictate specific testing protocols and standards that continually evolve to match the rapid advancements in technologies.

Serving Various Industries and Applications:

Electronics Validation:

Validating the electronic ecosystem, these chambers ensure the resilience of electronic components against thermal challenges, vital in the face of technological progress.

Automotive Scrutiny:

Playing a pivotal role in the automotive industry, these chambers scrutinize components destined for vehicles, from engine parts to electronic systems, ensuring durability on the road.

Aerospace Reliability:

In the aerospace sector, these chambers become indispensable for testing components bound for the sky, ensuring the reliability of aerospace equipment in extreme conditions.

Innovation Verification:

Industries driven by innovation embrace these chambers as vital tools.As breakthroughs propel industries forward, thermal testing becomes a cornerstone, validating the resilience and functionality of cutting-edge products.

How to choose RIUKAI Thermal Shock Chamber ?

Select a Thermal Shock Chamber with the following information:

1.Temperature range

The specifications tables of the thermal shock cabinets define the minimum (min) and maximum (max) temperatures achieved. Almost all climatic chamber manufacturers set the maximum temperature at + 150 ° ~ + 180 ° C, although if required this can be extended to + 200 ° C as a option. Although the maximum temperatures are almost always the same, the minimum temperatures of the chambers using a mechanical cooling system allow them to be divided into two broad categories:

✓ Single cooling system -20 ° ~ -40 ° C

✓ Dual cooling system -50 ° ~ -70 ° C

The dual refrigeration system consists of two refrigeration systems, consisting of two separate compressor units arranged in series so that very low temperatures can be reached.Sometimes a thermal shock cabinet with a chosen dual refrigeration system does not need to reach an exceptionally low temperature below the desired cooling level, but to have a rapid cooling rate at a low temperature.

2. Temperature exchange rate

The rate of increase or decrease in the temperature inside the test chamber is called the temperature exchange rate (expressed in Kelvins or degrees Celsius per minute) and can vary greatly from model to model. , from 6 ° C / min to 10 ° C / min.The rate of temperature exchange obviously depends on the cooling capacity of the compressor and the heating of the heating rod installed in the chamber. In other words, the stronger the compressor, the faster the cooling rate and the more heat bars are installed in the chamber, the faster the heating rate.The temperature exchange rates given in the thermal shock test cabinet specifications table generally refer to the equipment performance with the test cabinet being empty (i.e. without a test piece).

3.Volume (product dimensions and test chamber)

The main information to consider regarding the product to be tested is: product size, product material, product shape and weight of product under test.The size of the product allows you to determine the volume of the test cabinet, which is large enough to accommodate comfortably. It is generally best practice that the size of the test piece should not exceed one-third of the volume of the test chamber, although special consideration should be given to the shape of the product under test. In all cases the air shall be able to circulate freely to ensure that the variation and uniformity of temperature are almost equal (within the tolerance specified by the test) over the entire surface. of the test sample.

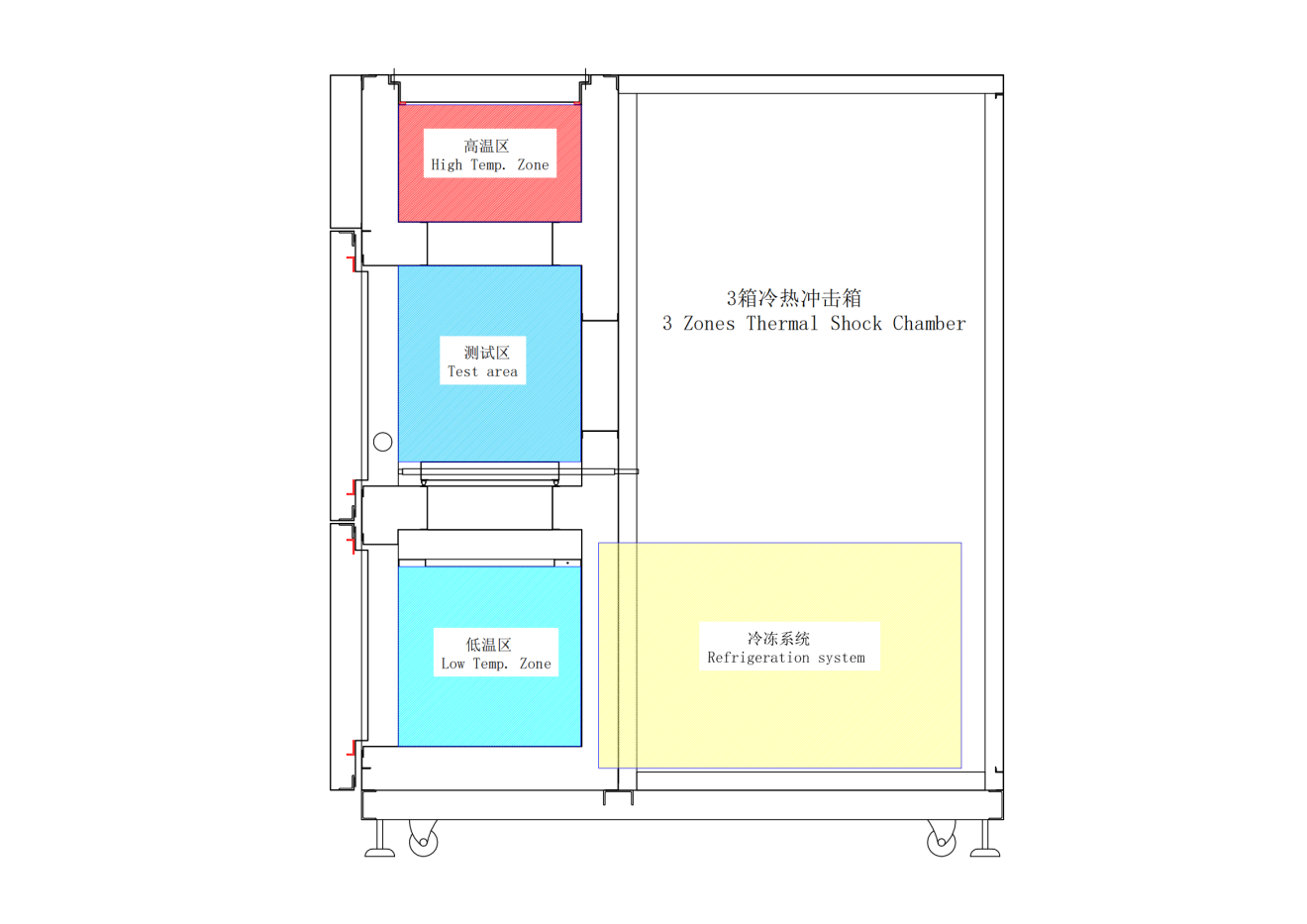

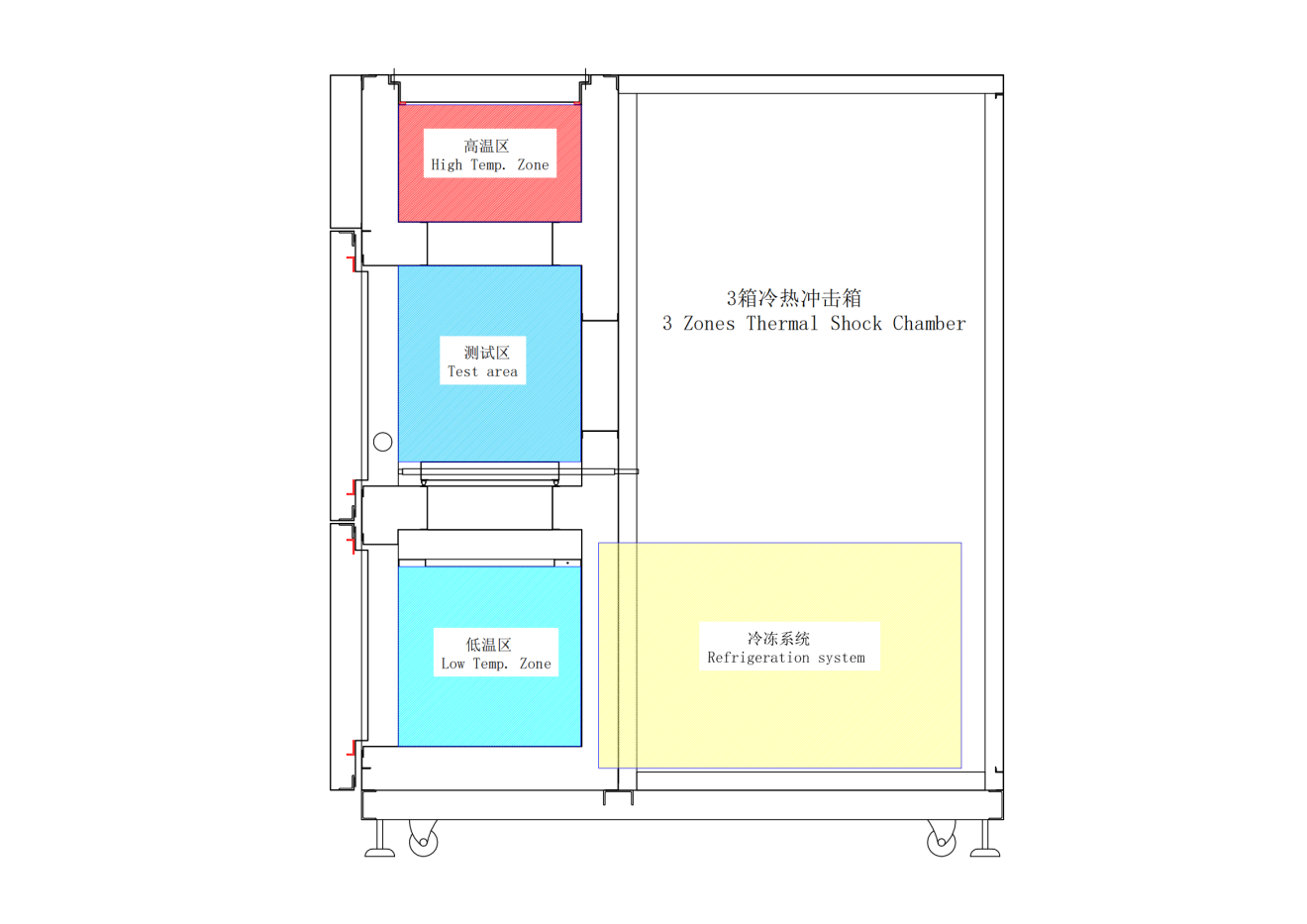

Thermal shock test chambers are designed for quick transitions between Cold and Hot temperature zones. These chambers are available in vertical and horizontal configurations, with two or three zones. The difference lies in the test method and internal construction.

The two-zone cold and hot thermal shock test is divided into a high-temperature zone and a low-temperature zone. The three-zone cold and hot thermal shock test is divided into a high temperature zones, a low temperature zones and a test area.

4.Sample weight

The weight of the test piece is also a very important parameter, as large volumes can adversely affect test performance: the performance of the climatic chambers, such as the temperature slope, calculated and specified with empty chamber, i.e. without any mass inside the test chamber. Therefore, when the required value of the required temperature exchange rate for the test piece is close to the value of the temperature exchange rate given in the technical data sheet (with empty chamber), it is necessary to carry out a home inspection. supply room.

Weight is a parameter that must be taken into account for another reason: the test cabinet racks are designed to support specimens up to a certain weight. Therefore, it is best to check the rating plate for what the maximum weight of the test piece is.If the test piece exceeds the maximum permissible weight, the cabinet accessories include a reinforced bracket or bracket.

5.Performance of the sample to be tested

Why Choose RIUKAI Thermal Shock Chamber ?

As industries and applications intertwine with the intricate dance of thermal testing, these chambers emerge not just as apparatus but as custodians of quality, reliability, and endurance. Their silent vigilance ensures that products, born from the crucible of innovation, stand resilient against the unforgiving touch of temperature.

Professional Guidance in Thermal Shock Testing (thermal shock chamber) with RIUKAI.Navigating the intricate landscape of thermal shock testing demands not just equipment but seasoned expertise. At RIUKAI, we bring forth a wealth of experience, having mastered the art of thermal shock testing over many years. Our commitment goes beyond providing testing chambers; we stand as your partners in ensuring the success of your tests.

Personalized Support:

Our team of thermal shock testing (thermal shock chamber) experts is dedicated to providing personalized support tailored to your unique challenges. We understand that each testing scenario is distinct, and our experts are ready to collaborate with you to ensure that your thermal shock tests(thermal shock chamber) are not just conducted but conducted with precision and relevance.

Comprehensive Solutions:

RIUKAI goes beyond being a provider of testing chambers; we are your partners in success. From suggesting suitable test conditions to guiding you on the right specifications, we offer end-to-end solutions that align with your goals. Trust in our expertise to navigate the complexities of thermal shock testing seamlessly.When it comes to thermal shock testing, RIUKAI isn’t just a supplier-we are your allies in achieving testing excellence. Rely on our experience, lean on our expertise, and let us guide you through the intricacies of thermal shock testing with confidence and precision. Your success is our priority!