RIUKAI TECHNOLOGY has 25 years of experience in the field of environmental testing equipment testing to meet the needs of our customers.

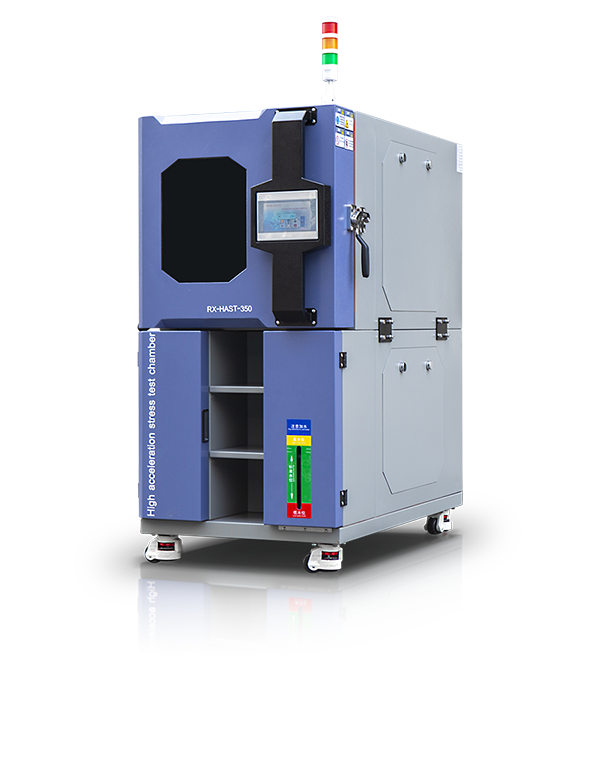

Pressure Test Chamber

Introduction of pressure test chamber

Pressure test chamber is a kind of environmental test chamber which can simulate the environment under different temperature, humidity and pressure conditions. Main products include Highly Accelerated Stress Test Chambers, Pressure Cooker Test chamber and Altitude Chamber / Hypobaric Chamber.

Highly Accelerated Stress Test (HAST) Chambers: These chambers are designed to accelerate the aging process of products by exposing them to high temperatures, humidity, and pressure. The aim is to quickly identify potential weaknesses in product design, materials, or manufacturing processes. HAST chambers are particularly useful in the electronics industry, where reliability and longevity of components like circuit boards and semiconductors are crucial.

Pressure Cooker Test Chambers: These are specialized chambers used to conduct accelerated stress testing under conditions of high temperature and pressure, often with saturated steam. These are employed to assess the dependability and steadiness of electronic components, especially in humid settings. Such testing is vital for products destined for exposure to severe environmental conditions.

Altitude/Hypobaric Chambers: Designed to mimic environments at high elevations, these chambers are instrumental in evaluating the performance of various products, notably in the aerospace and aviation sectors, under reduced pressure scenarios. Capable of emulating conditions from sea level to the stratosphere, they play a key role in guaranteeing the security and dependability of aircraft parts and other devices utilized in elevated altitudinal settings.

Each of these chambers serves a specific purpose in testing and ensuring product reliability under varying environmental conditions. They are essential tools in industries where products are expected to function reliably under extreme or variable conditions, such as in aerospace, defense, electronics, and automotive sectors.

With over 26 years of manufacturing experience, RIUKAI has become a specialized manufacturer and supplier of environmental test equipment.We sell different types of environmental testing chambers.

Contact us today for more information about our products and services. With 26 years of experience, RIUKAI’s team of engineers will help you find a solution to your environmental testing needs.

Category

Related Articles

Solution

Environmental Tests For Electric And Electronic Products – Part 2: Test Methods, Test m: Low Pressure

LCD Display Reliability Environment Test

Frequently Asked Question

A:RIUKAI has 25 years of experience in the industry. We can undertake the manufacturing and ODM cooperation of various large-scale non-standard environmental test equipment and provide environmental reliability test solutions.

A:Payment shall be made y T/T, L/C, or D/P, etc. We can communicate and negotiate.

A:Each machine will be debugged before shipment and shipped after debugging is completed. We will provide very specific operation manual and operation video, and also provide online remote video conference to guide the operation. We can provide on-site installation and training services abroad if customers require.

A:Generally, it takes about 20-30 days, and if we have it in stock, we can arrange delivery within 7 days. Please note that our production lead time depends on the number of items.

A: We provide various types of trade terms, such as EXW, CIF, DDU, DDP, etc.