RIUKAI TECHNOLOGY has 25 years of experience in the field of environmental testing equipment testing to meet the needs of our customers.

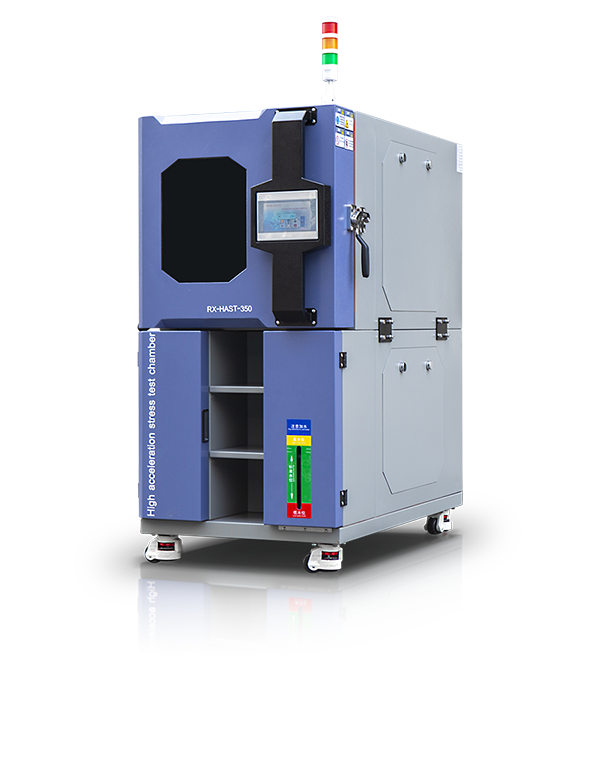

Highly Accelerated Stress Test Chambers

Introduction of the HAST Highly Accelerated Stress Test Chamber

The Highly Accelerated Stress Test Chamber (HAST) represents an expedited approach to testing the reliability of electronic components, where temperature and humidity are the key environmental factors.HAST aims to assess a sample’s resistance to humidity.

It does so by significantly elevating the water vapor pressure within the test chamber, well above the sample’s internal partial water vapor pressure. This method hastens the penetration of moisture into the test sample, providing a rapid assessment of its humidity resilience.

The RIUKAI RX Series HAST chambers significantly shorten the duration required for humidity testing of semiconductors.By raising the temperature above 100℃ and applying the corresponding pressure.These chambers can simulate standard humidity testing while retaining the same failure mechanisms.As a result, testing that traditionally takes weeks can be accomplished in just a few days.

Regarding the RIUKAI RX Series, it includes the following models: RX-HAST-350、RX-HAST-450、RX-HAST-550、RX-HAST-650.

Features of the HAST Chamber

HAST represents an intensified form of accelerated humidity-resistance evaluation. In comparison to standard high-temperature/high-humidity tests (conducted at 85°C/85% RH), HAST induces more pronounced moisture-induced corrosion and insulation degradation in components.

This method is primarily applied to plastic-sealed components. The accompanying table outlines the most prevalent HAST-related testing standards. Tests are conducted under specific temperature and relative humidity conditions, or pressure. Typically, the environment for HAST maintains a minimum temperature of 100°C under conditions of water vapor pressure.

HAST is available in both saturated and unsaturated forms; the former typically occurs at 121℃and 100% RH, while the latter at 110, 120, or 130℃ and 85% RH. Tests involving powered-on electronic components are generally of the unsaturated type.

As a test method, HAST is considerably rigorous, with an acceleration factor ranging from tens to hundreds of times more intense than conditions of 85℃ and 85% RH. Due to this extreme acceleration, it’s crucial to monitor for specific failure modes.

Category

Related Articles

Solution

Environmental Tests For Electric And Electronic Products – Part 2: Test Methods, Test m: Low Pressure

LCD Display Reliability Environment Test

Frequently Asked Question

A:RIUKAI has 25 years of experience in the industry. We can undertake the manufacturing and ODM cooperation of various large-scale non-standard environmental test equipment and provide environmental reliability test solutions.

A:Payment shall be made y T/T, L/C, or D/P, etc. We can communicate and negotiate.

A:Each machine will be debugged before shipment and shipped after debugging is completed. We will provide very specific operation manual and operation video, and also provide online remote video conference to guide the operation. We can provide on-site installation and training services abroad if customers require.

A:Generally, it takes about 20-30 days, and if we have it in stock, we can arrange delivery within 7 days. Please note that our production lead time depends on the number of items.

A: We provide various types of trade terms, such as EXW, CIF, DDU, DDP, etc.